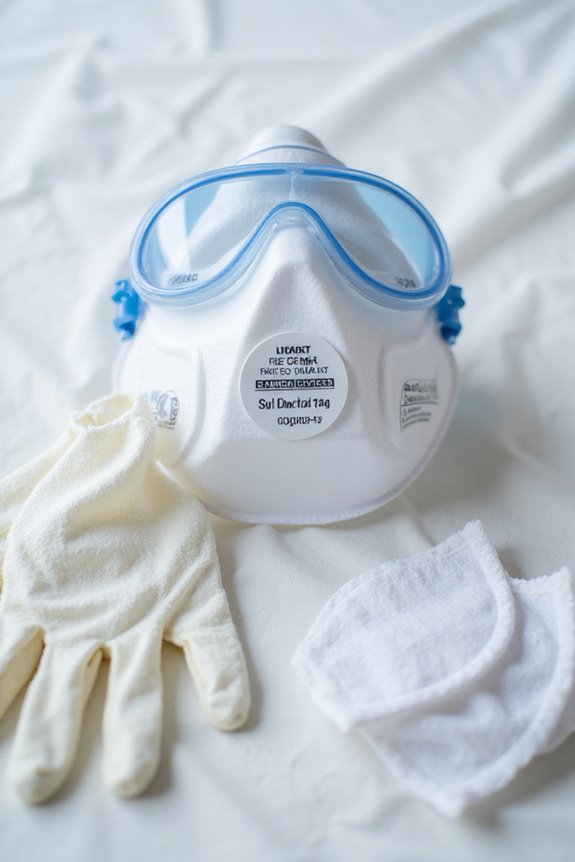

Using epoxy resin safely is essential for our health. First, let’s wear proper Personal Protective Equipment (PPE) like nitrile gloves, safety goggles, and an N95 respirator. 🧤👓 Next, we should set up a well-ventilated workspace free of flammable materials. Always mix and measure in a controlled manner, keeping spills at bay. Don’t forget to wash our skin if it comes into contact with resin and dispose of waste properly. 👍 There’s plenty more to discover about epoxy safety!

Key Takeaways

- Always wear appropriate personal protective equipment (PPE) such as nitrile gloves, safety goggles, and a properly fitting respirator.

- Set up your workspace with good ventilation, protective coverings, and well-organized materials to minimize spills and accidents.

- Avoid direct skin contact with epoxy by using application tools and promptly washing any exposed areas with soap and water.

- Regularly refresh your knowledge on safety protocols and participate in training sessions about epoxy handling and emergency procedures.

- Store resin and hardener in tightly sealed containers away from heat, and properly dispose of any waste materials to maintain safety.

Importance of Personal Protective Equipment (PPE)

When working with epoxy resin, it’s essential that we prioritize our safety by using Personal Protective Equipment (PPE). 🧤 This includes items like gloves, goggles, and respirators that protect us from harmful chemicals and irritants.

For PPE compliance, we need to select the right equipment. Choose nitrile gloves for protection against resin, as latex won’t do. Remember, proper eye protection is a must—safety goggles keep our eyes safe from splashes and dust.

When it comes to respiratory health, we should use respirators with an N95 rating or better. For longer jobs, consider vapor masks to filter chemical exposure. Additionally, non-toxic formulations can help minimize health risks while working with epoxy resin.

Setting Up a Safe Workspace

Here are a few key tips to contemplate:

- Workspace Layout: Organize your area by keeping frequently used tools nearby. This minimizes unnecessary movement, reducing spill risk.

- Surface Protection: Cover work surfaces with disposable plastic sheets or silicone mats. This aids with spill prevention by catching drips.

- Ventilation: Guarantee good airflow with open windows or fans. This reduces harmful fumes while you work.

- Cleanup Supplies: Keep absorbent materials like paper towels handy for quick spill management.

- Lighting: Good lighting is essential for precise mixing. It can reduce mistakes that lead to waste.

- Material Quality: Always choose kits with high-quality material quality to ensure safe and effective resin use.

Let’s create a workspace that prioritizes our safety while we enjoy working with epoxy resin!

Proper Handling Techniques

To guarantee a safe experience while working with epoxy resin, we must prioritize proper handling techniques right from the start. Here are some key points to remember:

- Wear gloves (nitrile or butyl rubber) to create a chemical barrier. 🙌

- Use tools like spatulas for epoxy application techniques, avoiding direct hand contact.

- Always work in well-ventilated areas to minimize contamination from fumes. 🌬

- Avoid eating or drinking in the workspace to prevent accidental ingestion. 🍽

- Store resin and hardener in tightly sealed containers, away from heat.

- Clean surfaces and tools right after use with suitable solvents. Additionally, ensure the use of safety gear to protect yourself from potential hazards while working with resin.

Understanding Respiratory Protection

Proper handling techniques can greatly enhance our safety, but understanding respiratory protection is just as important when working with epoxy resin.

When we don’t have adequate ventilation, wearing a respirator becomes essential. Regular dust masks or N95s won’t filter harmful epoxy vapors effectively. Instead, we should use respirator types equipped with organic vapor cartridges and particulate filters.

Here are some key tips:

- Use respirators during sanding or heating processes.

- Replace cartridges regularly for ongoing safety.

- Fit the respirator correctly for full protection from fumes and dust.

Always check exposure limits for the specific epoxy product we’re using, as inhalation can lead to irritation and long-term respiratory issues. Additionally, it’s crucial to ensure that we are aware of the safety precautions mentioned in the product specifications to minimize health risks. Let’s prioritize our safety with proper respirators!

Maintaining Eye and Skin Safety

When working with epoxy resin, we need to protect our eyes from potential eye hazards. Always wear safety goggles that fully surround our eyes. They keep splashes and fumes at bay better than regular glasses. If resin gets in our eyes, we should flush them with water for at least 15 minutes. Don’t hesitate to seek medical help if we have ongoing irritation.

For our skin, we must wear disposable nitrile gloves. This prevents skin irritation and reduces the risk of rashes. Covering our arms with long sleeves can provide extra protection. If we do come into contact with epoxy, let’s wash the skin thoroughly with soap and water to remove any remaining residue. Additionally, using protective gloves is a crucial step in ensuring safety while crafting! Stay safe while crafting!

Effective Ventilation Practices

Effective ventilation practices are essential for guaranteeing our safety while working with epoxy resin. To start, we need to assess airflow in our workspace. Natural ventilation, like opening windows, might not be enough, so let’s consider using mechanical ventilation systems. Here are some tips:

- Create Cross-Ventilation: Open windows or doors on opposite sides of the room. 🌬

- Use Fans: Both ceiling and portable fans help circulate air effectively.

- Install Exhaust Fans: They should vent air outside in enclosed areas.

- Check Air Quality: Regularly perform airflow assessments to verify everything’s working.

Safe Mixing and Measuring of Epoxy

To guarantee we mix epoxy resin safely and effectively, accuracy in both measuring and mixing is essential. Here are some helpful tips:

🔹 Measuring Techniques:

- Use dedicated containers for each component to avoid cross-contamination.

- Opt for graduated cups or syringes to achieve precise ratios.

🔹 Mixing Procedures:

- Always pour resin and hardener into a clean third container.

- Stir slowly to prevent air bubbles and make certain of a uniform blend.

- Use non-reactive stir sticks for effective scraping.

Correct Disposal Methods

Proper disposal of epoxy resin is essential not only for safety but also for environmental protection. When we handle unmixed resin or hardener, we must remember they’re considered hazardous waste. Instead of throwing them in the trash, let’s take them to hazardous waste collection centers.

🗑 Here are some important tips:

- Mixing: Combine resin and hardener in correct ratios and let them fully cure.

- Cured Waste: Fully cured epoxy is nonhazardous and can go in regular trash.

- Labeling: Keep original labels on containers—this helps waste management identify materials.

- Transport: Seal containers tightly to prevent leaks.

Recognizing Signs of Exposure

Respiratory Symptoms: Watch for difficulty breathing or a persistent cough, which could indicate irritation from fumes. We need to prioritize symptom recognition during any epoxy use.

- Throat swelling can lead to hoarseness or a muffled voice, alerting us to possible exposure.

- Persistent coughing or shortness of breath signals inhalation overexposure.

- If we notice eye irritation, such as redness or tearing, it’s crucial to assess our exposure level.

Also, be aware of gastrointestinal symptoms like abdominal pain or vomiting, as these may indicate a serious reaction.

Recognizing these signs early can help us take action quickly and guarantee our safety while working with epoxy resin. Let’s stay alert and protect ourselves! 😊

Educating Yourself on Epoxy Safety

When working with epoxy resin, understanding how to stay safe is just as important as recognizing the signs of exposure. We need to educate ourselves about epoxy hazards and guarantee safety training is part of our routine.

🔍 Here are some key points to reflect upon:

- Check MSDS: These sheets provide vital safety info on the epoxy you’re using.

- Use PPE: Nitrile gloves, safety goggles, and respirators are essential for protection.

- Ventilate: Make certain your workspace has proper ventilation to minimize inhalation risks.

- Practice Hygiene: Avoid skin contact and wash exposed areas immediately.

Regular training and awareness can greatly reduce risks, helping us stay safe while enjoying our epoxy projects!

Frequently Asked Questions

Can I Use Epoxy Resin Indoors Without Any Ventilation?

We can’t use epoxy resin indoors without adequate ventilation. Epoxy fumes pose health risks, and ensuring proper airflow is essential to disperse these fumes and maintain a safe working environment while minimizing exposure.

What to Do if I Accidentally Ingest Epoxy Resin?

If we find ourselves in a sticky situation after ingesting epoxy resin, we must act quickly. Recognizing epoxy toxicity symptoms, we’ll seek emergency medical response—no time for hesitation when our health is on the line.

How Long Does Epoxy Take to Cure Completely?

When we consider epoxy’s cure time, it usually takes about 7 days for full hardness. However, temperature effects can accelerate or delay this process, so it’s crucial we maintain ideal conditions for best results.

Is Epoxy Resin Safe for Food Contact Surfaces?

Like a chef choosing the perfect ingredients, we need to select food safe options in epoxy brands. When properly cured, specific resins can be safe for food contact surfaces, but we must always check certifications.

Can I Use Epoxy Resin in High Humidity Conditions?

We can use epoxy resin in high humidity, but we should be cautious. Humidity effects on epoxy adhesion can result in tacky surfaces and imperfections, so it’s best to guarantee conditions are right before starting our project.